Introduction

The Eos Solutions Product Configurator for Manufacturing app allows you to create routings and production BOMs with work centers, run times, and BOM's components that vary according to the value of the characteristics.

Subscription |

|---|

|

Some features of the Product Configurator for Manufacturing (CFG) app require a subscription. The subscription can be activated from the SUBSCRIPTION CONTROL PANEL or directly from the notification messages that the system proposes, by clicking on the link that allows you to start the subscription wizard. See Eos Solutions website for more details. |

| Additional App |

|

Install Product Configurator (CFG) to manage, on the sales side, the product configuration both through the generation of item codes and through the generation of variants. The Product Configurator (CFG) app, through the use of characteristics and configuration rules, allows you to:

|

Production Bill Of Material

The product configurator allows to automatically generate punctual production BOMs starting from a neutral BOM. The expected features are:

-

Automatic calculation of quantities of use through formulas based on characteristic values.

-

Condition the presence of a particular component with a value-based condition on characteristics.

-

Condition the component code according to the characteristics.

Routings

The product configurator allows to automatically generate punctual Routing starting from a neutral Routing. The expected features are:

-

Automatic calculation of setup / run times through formulas based on the values of the characteristics.

-

Condition the presence of a certain phase of the routing with a condition based on the characteristics.

-

Condition the code of the work center / machine center according to the values of the characteristics. Processing Logics managements.

How it works

Within the Order, for items that are created by the Configurator, the system generates the BOM. We open it from Line->Related Information-> Structure:

The BOMs you create are multilevel, for example:

Configurator tab

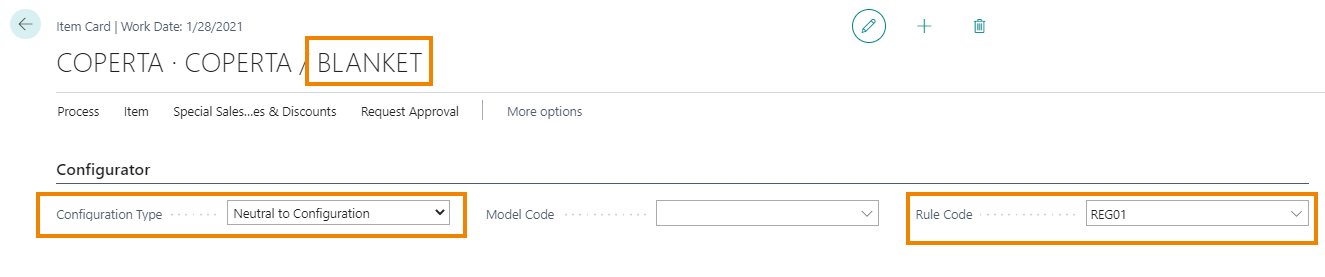

We consider, for example, the item "BLANKET".

In order to use the Configurator it is necessary to start from a "neutral" item and in the item card you need to:

- enable the Configurator Management (select "Neutral to Configurator")

- define a Rule Code

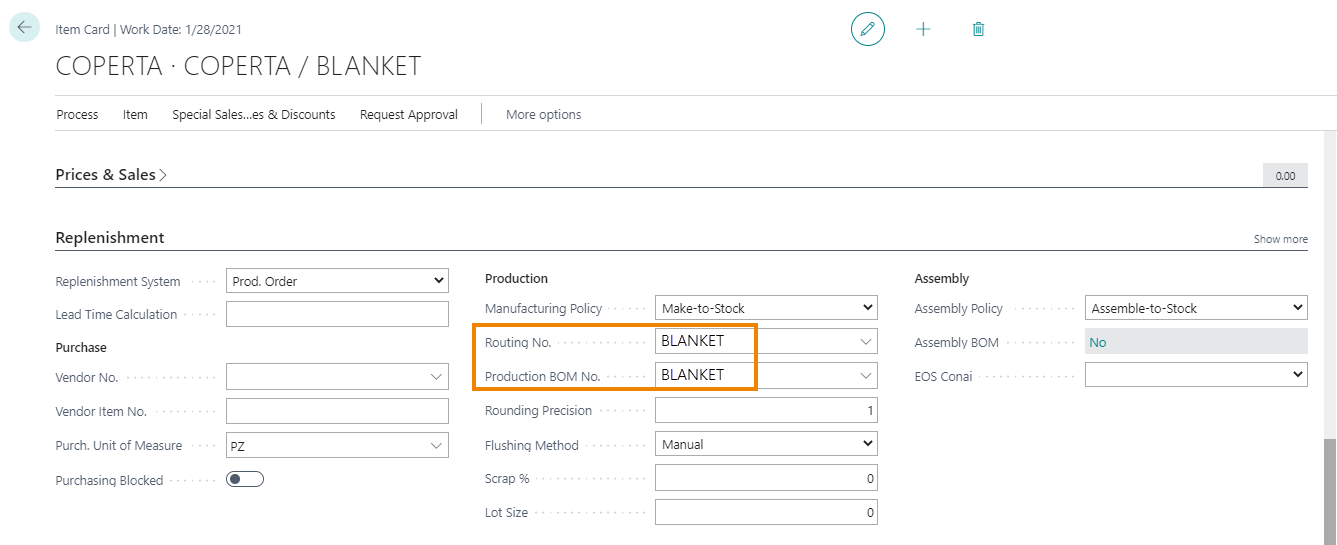

Replenishment tab

In addition, this production item must be associated with a Routing that is also considered neutral and a neutral BOM:

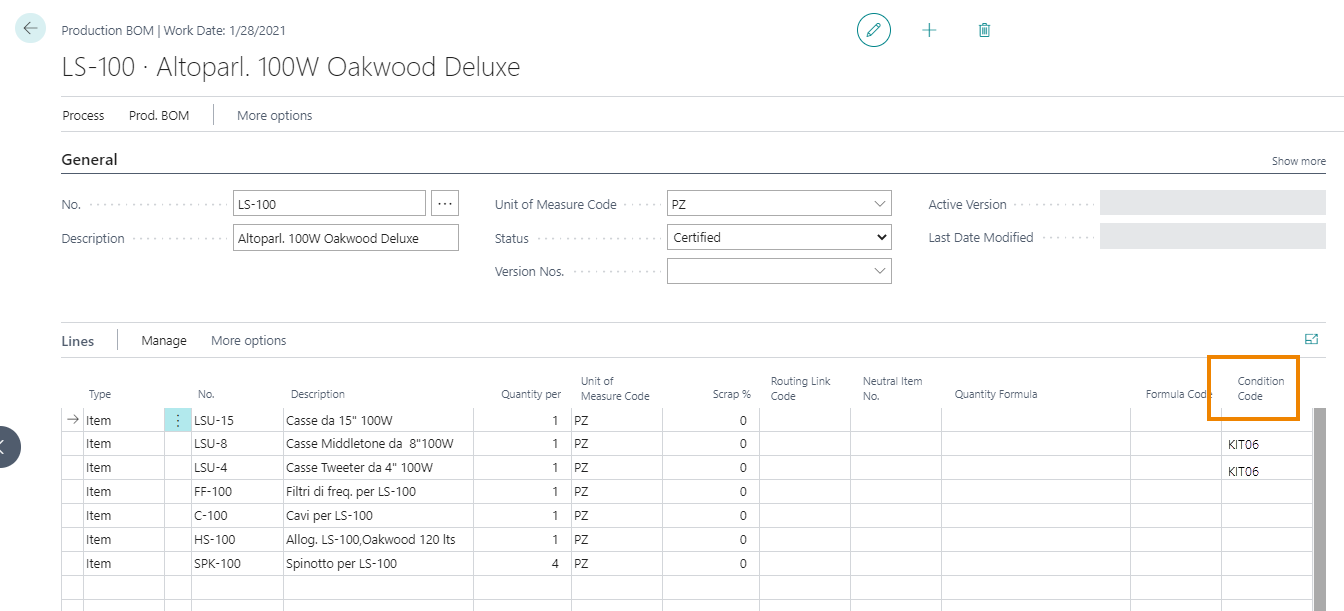

Bill of Material

The Bill of Material (BOM) of the neutral item contains a single item (e.g. Fabric) whose quantity will be equal to the characteristic S=surface (square meter)

In the configured BOM the system replaced the code (Fabric C 01), the item and the quantity of use (2):

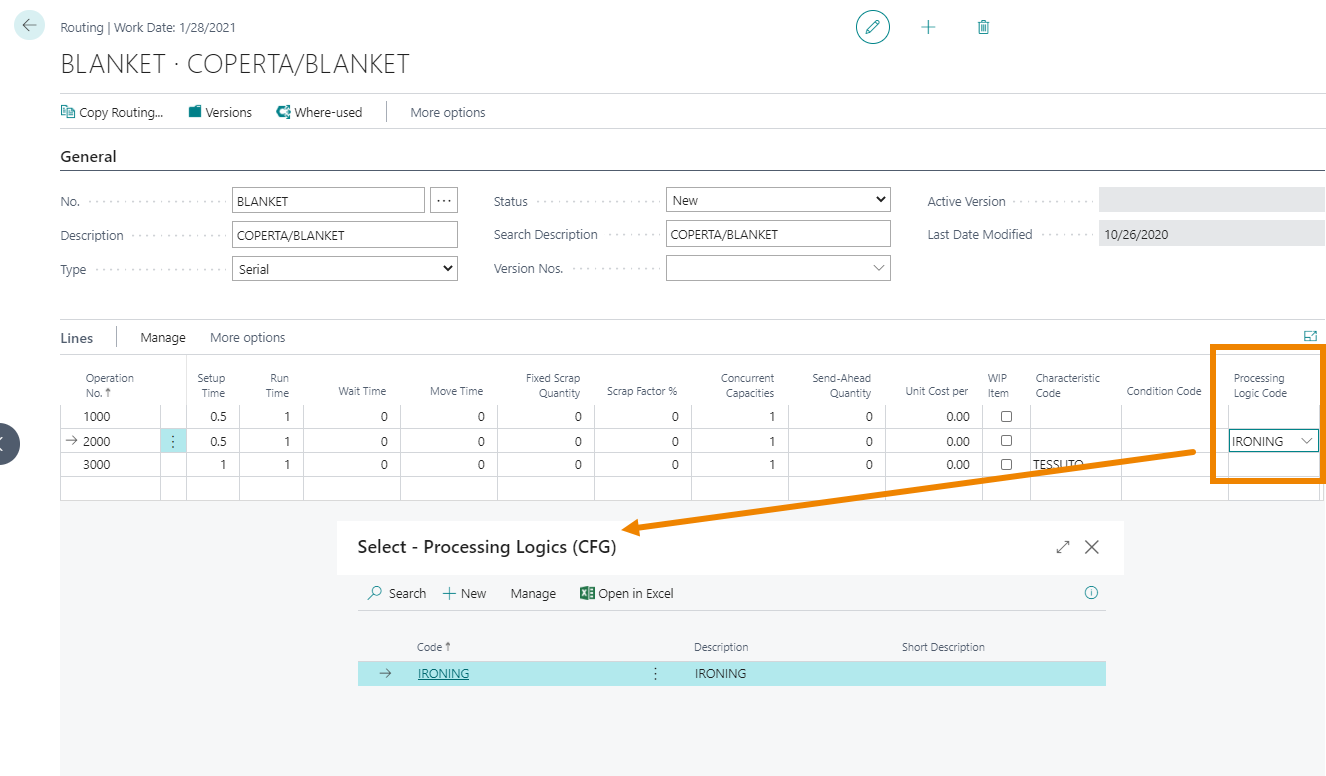

Routing

The example for the neutral item contains three tasks with specific setup and run times. The phases can be linked to Conditions or Characteristics.

Second and third phase are conditioned to a Condition Code and a Characteristic Code:

In lookup:

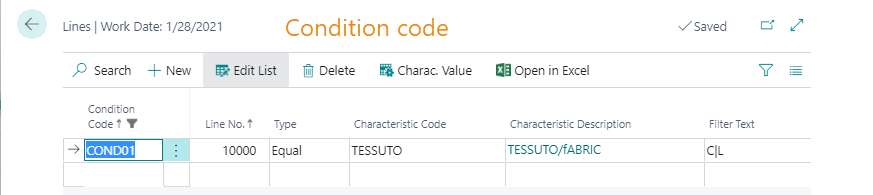

For example, the Condition applied to the "Ironing" phase states that this stage of the routing will be applied if the characteristic takes the values "C=Cotton" or "L=Wool".

The Packaging phase, on the other hand, is linked to a characteristic code. Opening the lookup we see that depending on the fabric you can choose whether or not to enable the phase and decide which work center to use:

You can also specify a run time factor and a standard task to apply to the phase.

N.B. |

|---|

|

The Condition Code also applies to BOM component lines (the component will be present in the BOM depending on the condition):

|

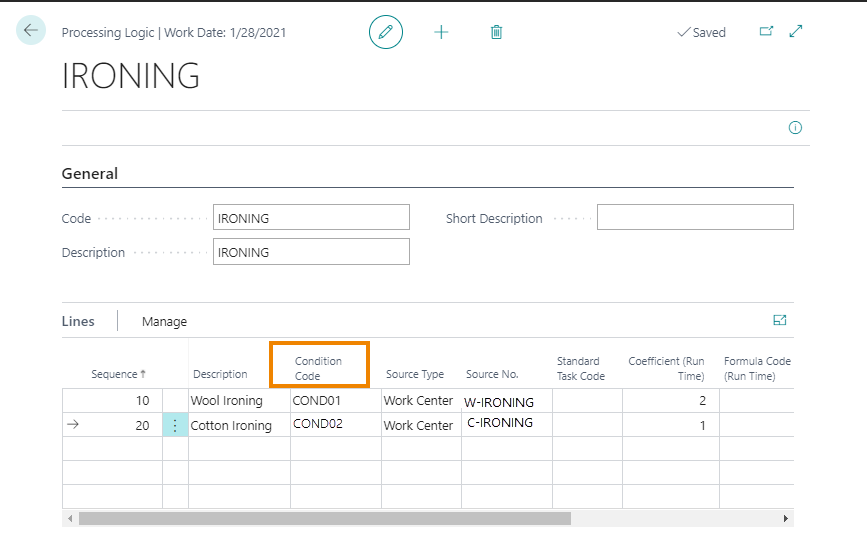

The phases can also be linked to a Processing Logic Code, which binds Characteristic Code and Condition Code allowing you not to have too many lines within the neutral article.

In lookup Manage->Edit:

you can insert N-lines sequentially with Work Centers related to Condition Codes, Std Task Codes, and Coefficients for setup and run times. The system reads the lines sequentially and applies the processing logics. If none of the processing logics is true, it means that the routing phase is not expected and therefore the configurator deletes it.

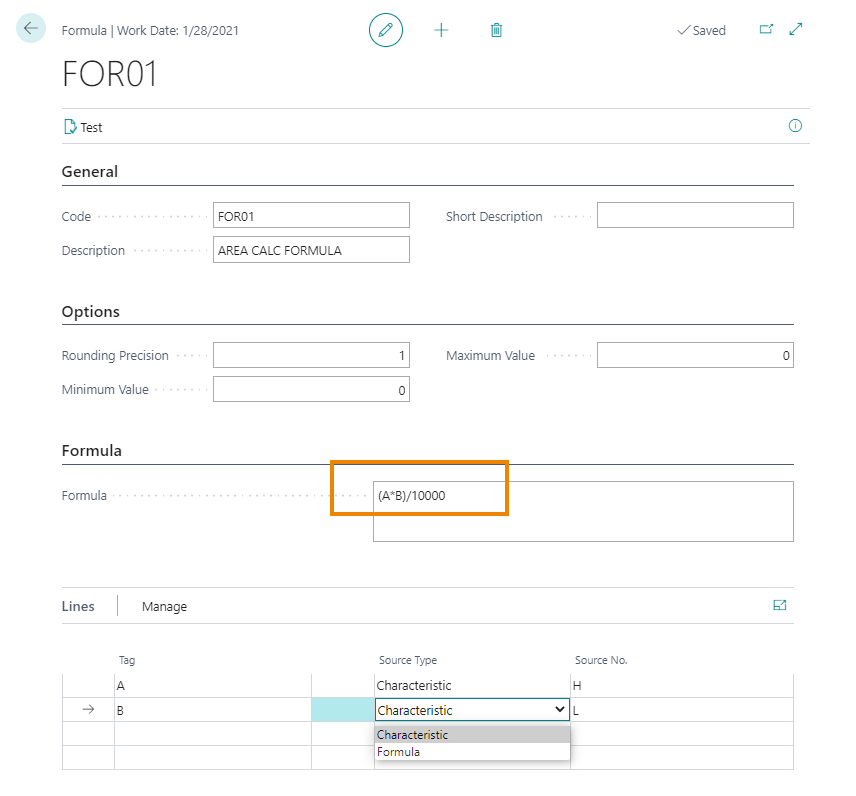

Formula code (Run Time):

Within processing logics, this field allows you to manage processing formulas without inserting them directly into the BOM so that you can easily update/modify them. It is possible to set the different formulas by defining the calculation to be made.

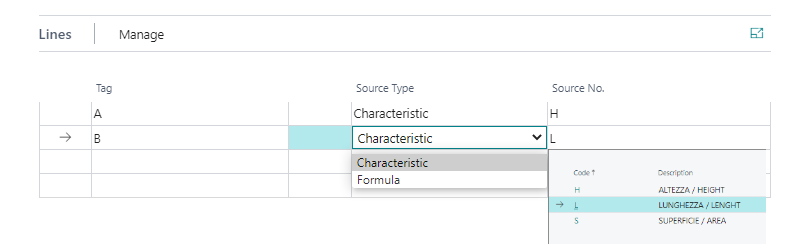

In lookup, or on page Formulas (CFG):

Each formula may depend on the characteristics or also on other formulae

If it is necessary to modify a formula you can do this by opening its card and then from the Item List we open the item of interest and from Actions->Configurator->Configured Item we see the variants created.

Now just press Reconfigure Variants to have the system update them all together by reapplying Rules and Formulas and regenerating Items and BOMs