MPS, MRP planned execution with Job queue

It is possible to plan the execution of MPS, MRP and the distribution of reports by applying some criteria and filters.

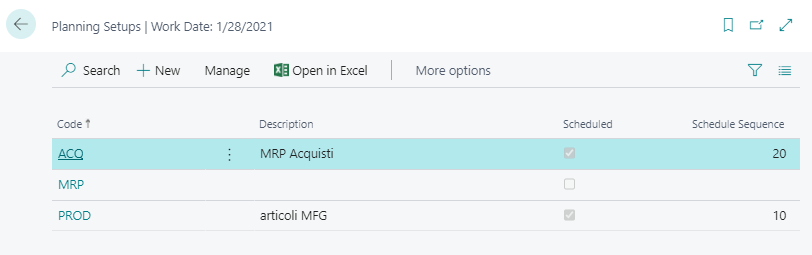

In Planning Setups (MPL), you can set up different setup configurations for the system to perform planning calculations.

After inserting several configuration lines, it is also possible to make them run according to a specific sequence, for example:

- MPS and production items only

- MPS and purchase items only

- MRP for production items only

- MRP for purchase items only

Tab General

| Field | Description |

| Code, Description | set a code and description for the setup line |

| Scheduled | establish if the setup is to be scheduled |

| Schedule Sequence | if the setup is scheduled, set the phase of the planning sequence |

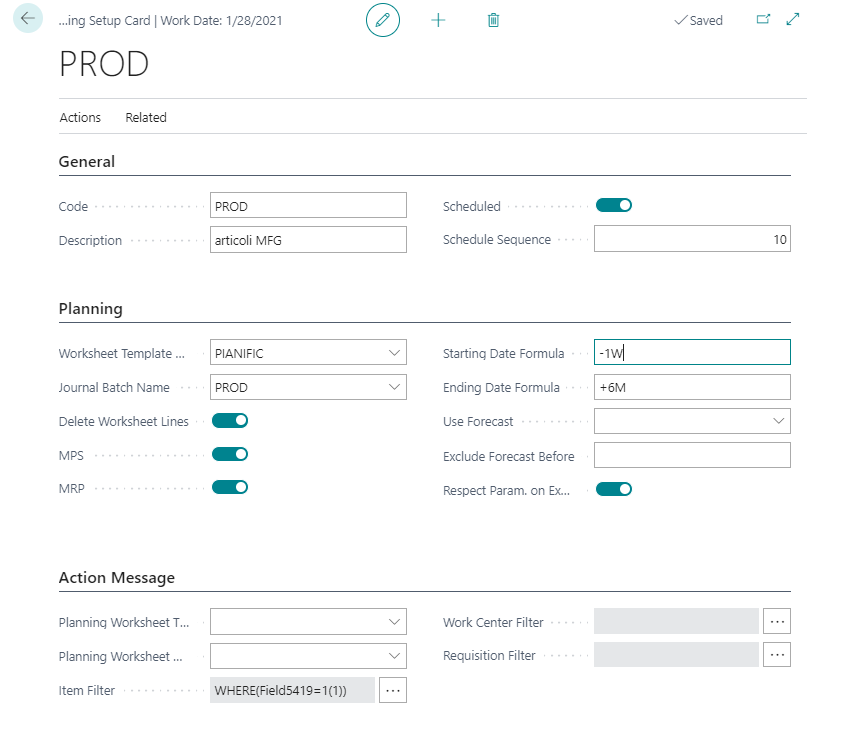

Tab Planning

| Field | Description |

| Worksheet Template Name | choose the template name |

| Journal Batch Name | select a batch on which the entries will be posted |

| Delete Worksheet Lines | when planning starts, choose whether to delete the lines in the corresponding worksheet |

| MPS, MRP | choose if you want to calculate the MPS and / or the MRP |

| Starting Date Formula / Ending Date Formula | enter a formula for the planning start / end date |

| Use Forecast | you can use a forecast made previously |

| Exclude Forecast Before | set a date before which you want to exclude the schedule |

| Respect Param. on Exception | choose whether to respect these parameters |

Action Message

| Field | Description |

| Planning Worksheet Template / Name | it is possible to define a Planning template and name on which the calculation is to be distributed |

| Item Filter | it is possible to filter by item (eg all items with "Prod. Order" supply system) |

| Work Center Filter / Requisition Filter | it is also possible to filter by work center / requisition |

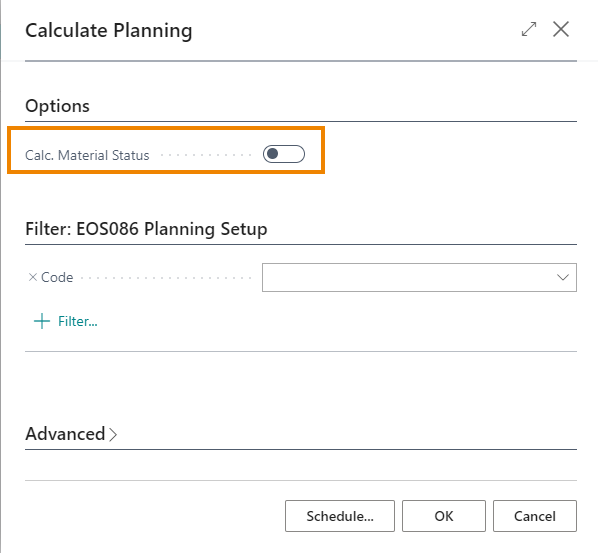

Through Related-> Calculate planning it is possible to execute the planning as set up and it is also possible to calculate the material status .

See also:

| Introduction |

| Sequence planning - setup |

| Material status |