Equipment and personnel

| Summary |

| Main features |

| Personnel and equipment - masterdata |

| Personnel and equipment - use |

A work center can be identified as:

-

Tool

-

Person

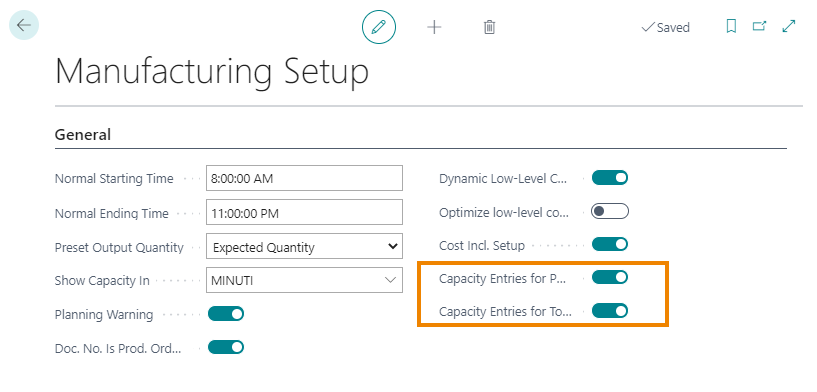

This allows you to consider these two aspects in routings and consequently in production orders. You can use these areas for informational purposes only, or you can consider them in capacity movements, in terms of setup and run times, to which you can associate costs. Simply activate the corresponding option on the Manufacturing Setup tab:

Personnel / equipment - masterdata

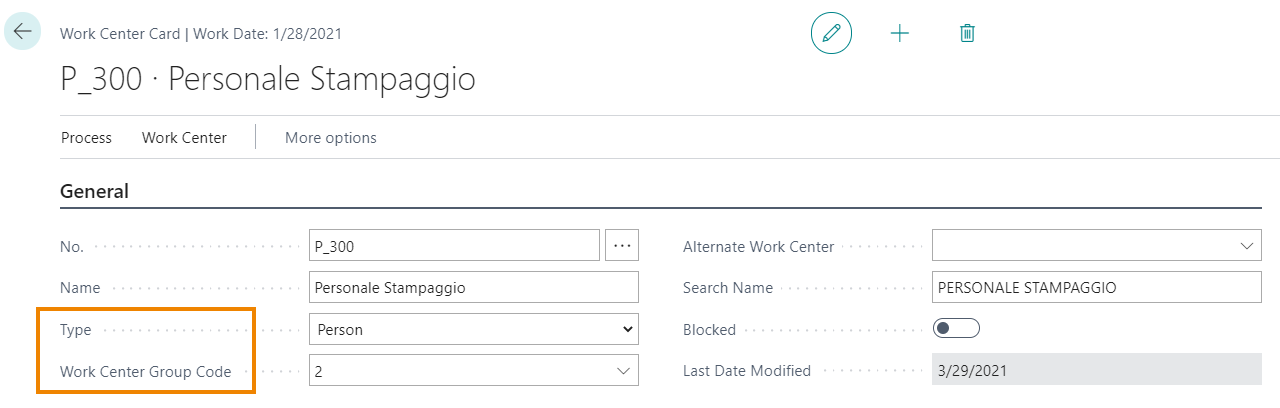

A work area can be of type "Tool" or "Person" and have a specific Work Center Group Code.

The other fields are filled in in the same way as classic work centers.

| Field | Description |

| Type |

|

-

Personnel in routings

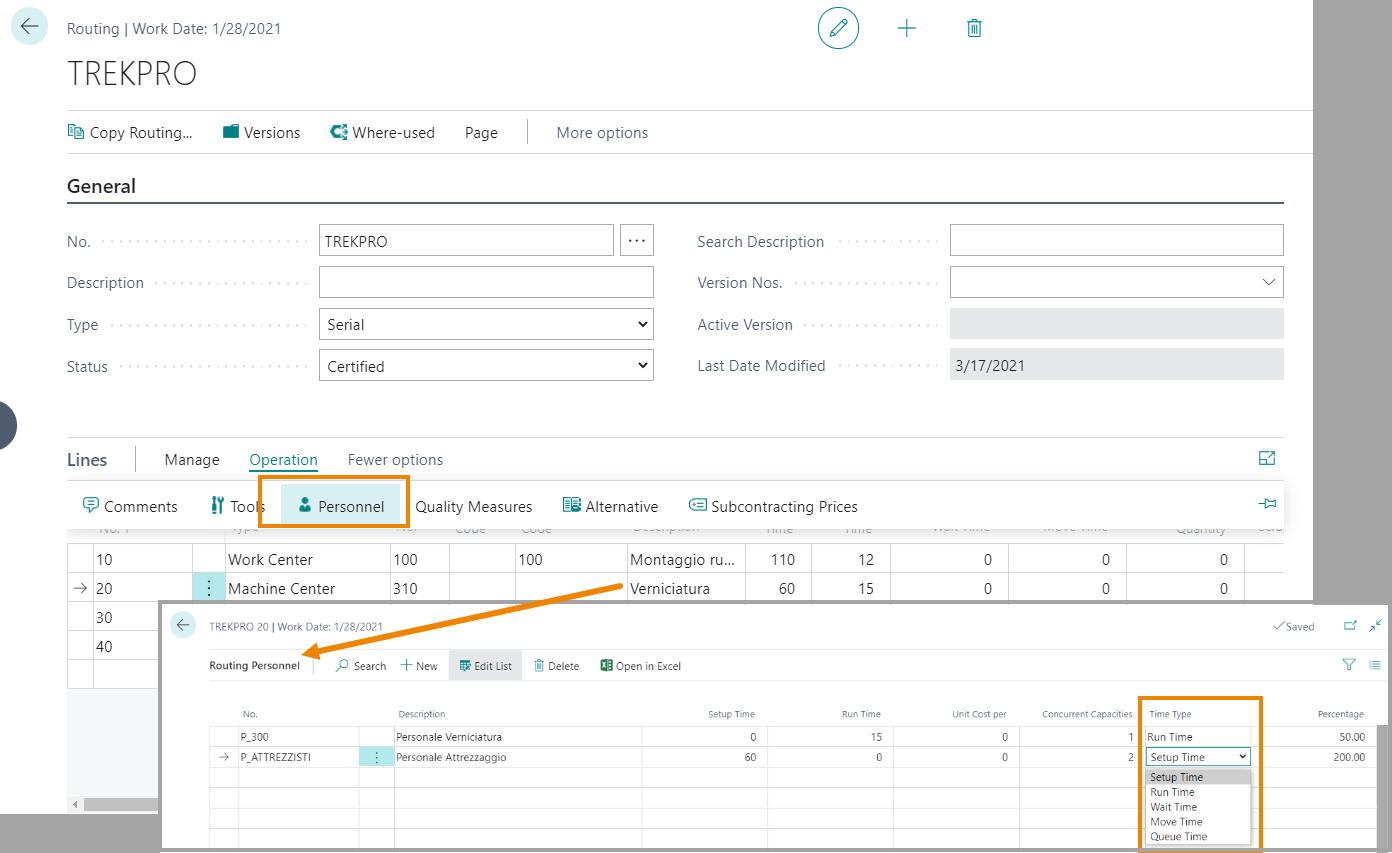

It is possible to insert one or more "Personnel" work centers within a routing .

It is possible to indicate a specific Unit Cost for the processing cycle diifferent from the cost attributed in the personnel masterdata.

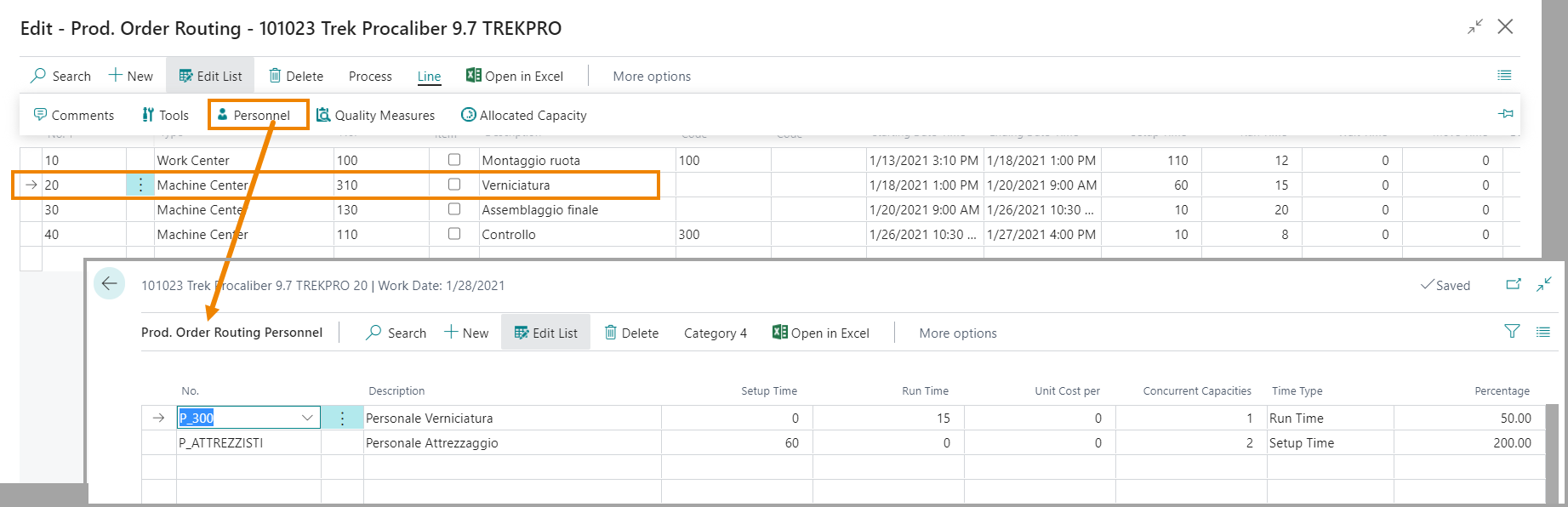

E.g. for the TREKPRO routing we select the "Verniciatura (Painting)" work center and from Operation-> Personnel we can get the details on the people who work for this center:

Specifically, we have defined that in the Painting work center there are people who take care of the actual painting and some equipment installers who follow the setup instead.

NB Setup Time, Run Time and Concurrent Capacities are used by the system for cost calculation.

| Field | Description |

| Time Type | the Personal area is associated with a capacity expressed in terms of time, based on the corresponding Type of Time: Setup Time, Run Time, Wait Time, Move Time, Queue Time. |

| Percentage | indicates the percentage of employment of the personnel (one person is employed for the painting, for 50% of their working time. The setup is followed by two people, each of whom takes all their working time.) |

-

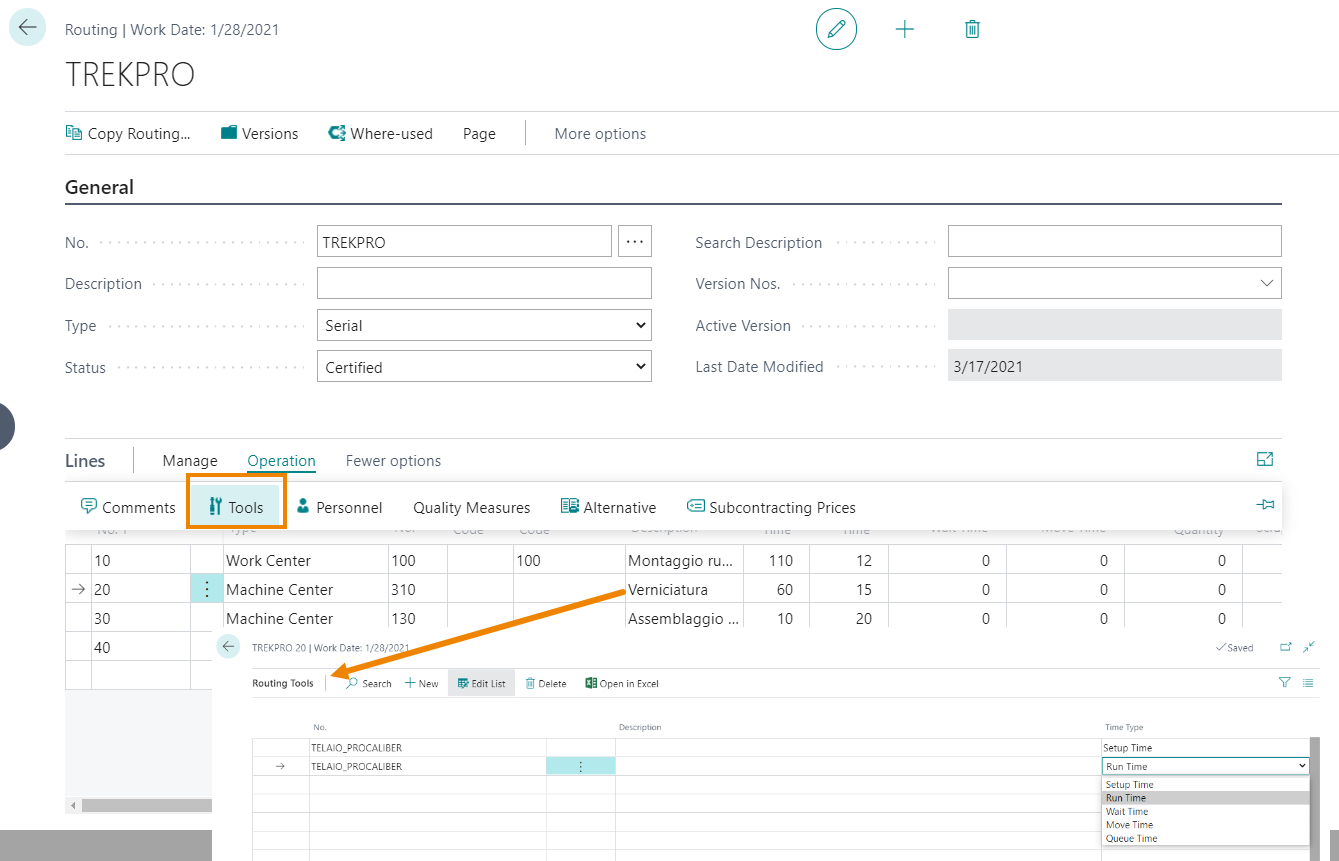

Tools in routings

It is possible to insert one or more "Tool" Work Center within a routing . The equipment is associated with one or more Time Type, based on the time it is used, including: Setup Time, Run Time, Wait Time, Move Time, Queue Time.

E.g. for the TREKPRO cycle we select the "Verniciatura (Painting)" work center and from Operation-> Tools we can have the detail on the frame that is needed for the painting:

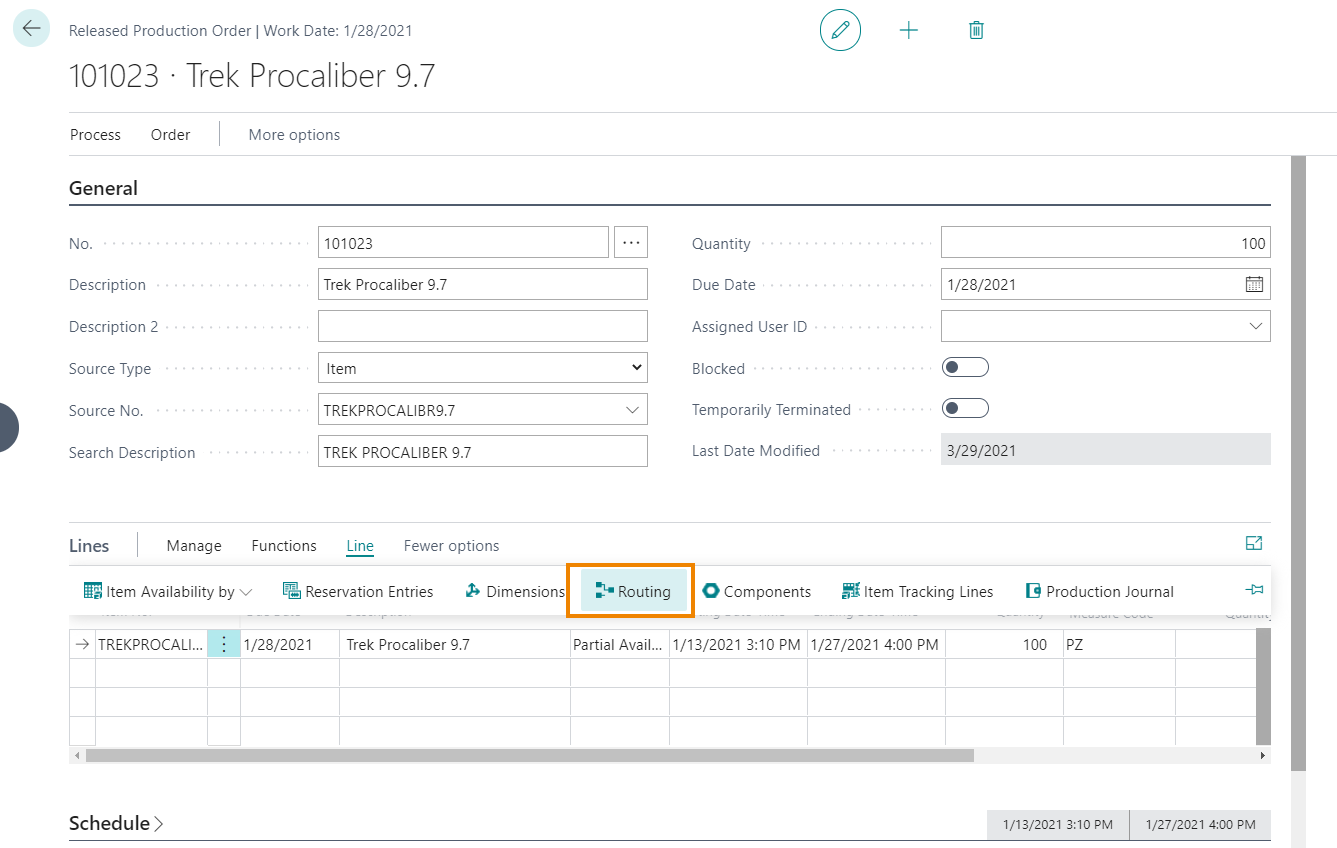

Production order

From Line ->Routing we can see the details relating to the production order operations:

By selecting an operation (e.g. Painting) from Line -> Personnel we can have the details of the people working on the painting

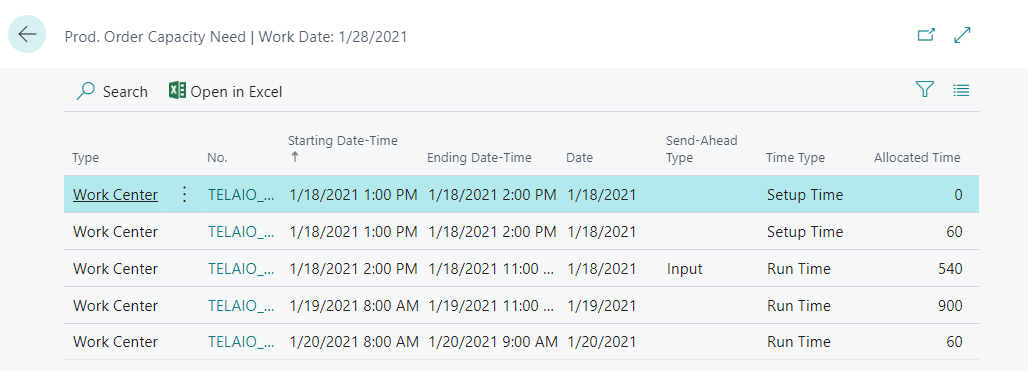

From Related- >Allocated Capacity we can see the capacity need:

Similarly for the equipment:

It is possible to check the work load of the personal / tools work center based on the allocated capacity. On the Work Center card from Related-> Production Area-> Load:

It is possible to see the loads by day, week, month, quarter, year, period. In the same way you can view the workload for the equipment:

See also:

Massively change BOM or production order components